Disclaimer: PCBWay provided free PCBs for this review. No other compensation was provided. PCBWay did not request nor receive favourable treatment.

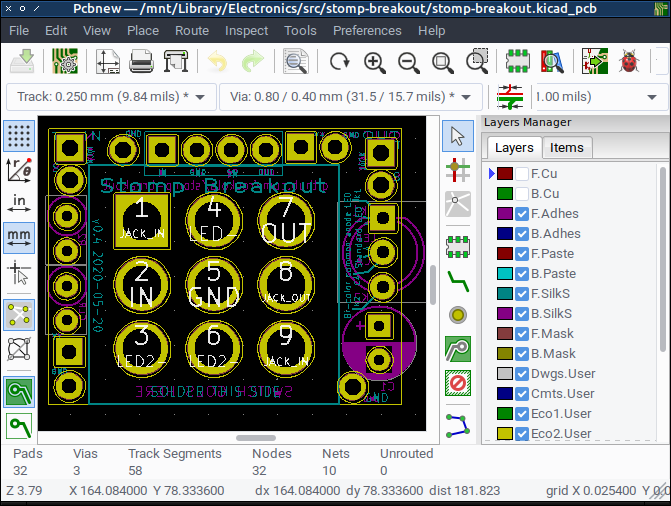

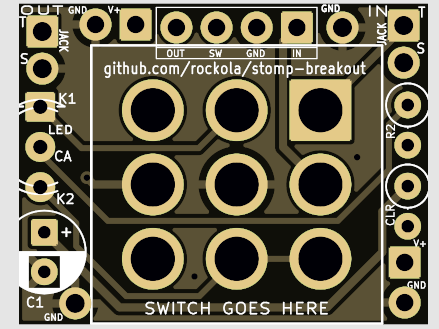

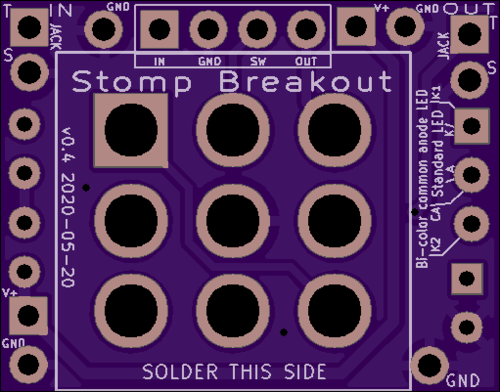

The following is a 3-way shoot-out review between 3 PCB manufacturers: PCBWay and JLCPCB in China, and Oshpark in the US. I uploaded the same Gerber files to each of them. I’ve reviewed both the order process and the finished product. You can download my KiCAD files (warning: I used the development nightly version) from Github: https://github.com/rockola/stomp-breakout/

PCBWay

The front page has an “Instant Quote” box, which is great, no need to click and click again to get down to business. For some reason though I need to input the dimensions (length and width) of my PCB – why can’t I just upload my Gerber file which contains that information along with everything else needed for the quote (and indeed manufacture of the PCB)? (Update: clicking “Quick Order” lets you upload a Gerber. I don’t know why this is not on the default page.) Just a nitpick, not a problem to give those along with the other required data: quantity (from 5 up in steps of 5), number of layers (this could also be read from the Gerber) and PCB thickness (0.4–2.4mm, default 1.6mm).

Clicking “Instant Quote” opens another page with further options, including panelization either by the customer or PCBWay. I did not try this, partly because I did not need it and also because the instructions for customer panelization are vague. An email to customer support did not really clarify things much. Selecting “Panel by PCBWay” opens a free-text field for the panel requirements such as dimensions. This is unnecessarily error-prone (will the operator understand my message as intended?) and should be replaced with constrained width x height input fields. Maybe I’ll get back to testing panelization at a later date.

There are a number of options that can be selected. Dauntingly so in fact, but luckily the defaults are sensible.

PCB material can be “FR-4” (basic fiberglass, the default) , “Aluminum”, “Rogers” (the tooltip says ‘A special base material, a kind of RF PCB and High Frequency PCB, which have less lossy at high frequencies.’), “Copper Base”, or “HDI (Buried/blind vias)” for multilayer (4 or more layers) boards. Choosing anything other than FR-4 can get expensive real fast though. Even for FR-4, there are three choices for glass transition temperature; in this application there will be no heat stress so I picked the default.

Board thickness can be selected in the 0.2–3.2mm range; I’d like to give the really thin ones a go at some point as a PCB business card. I went with the 1.6mm default.

There are 10 different solder mask colours (including “None”), some more expensive than others. I went with the red for no particular reason, there was no surcharge compared with the default green. “Matte black” sounds gorgeous but is quite a bit more expensive. Silkscreen colour is either white or black depending on solder mask colour; yellow solder mask can go with either.

Surface finish can be one of 9 options, ranging from leaded HASL to immersion silver, which is surprisingly more expensive (but not by much) than hard gold. I went with lead-free HASL, which is more expensive than HASL with lead, but complies with EU environmental regulations. I think I’ll consider going with ENIG (immersion gold) in the future.

Copper thickness defaults to “1 oz Cu”, which means a square foot of PCB covered completely with copper would have 1 ounce (28 grams for those of us using sane units) of copper on it. Thicker copper is of course more expensive. If track width and spacing is under 8 mil, only 1 oz Cu and 2 oz Cu are available, otherwise it can go up to 13 oz Cu (that’s a load of copper).

There is a box to tick to remove order number from PCB for $3. If left unticked, there will be a serial number on the silkscreen somewhere on the board for factory internal use.

When all the PCB options have been selected, a shipping option needs to be picked. I went with DHL, which is of course faster (and more expensive) than China Post. Then it’s time to save the order in the shopping cart – and now we can finally upload the Gerbers!

The PCBWay Gerber viewer has SVG download, which can be handy. PNG download would have saved me from a SVG-to-PNG render step, but that’s neither here nor there.

Uploaded Gerbers are reviewed before the order can be submitted. This should not take more than a few minutes (during their business hours at least). My Gerbers were uploaded on 2020-05-20 at 09:20. There was a slight delay as I waited for my coupon (see note in the beginning of this review). My order specifications were:

- 2 layers

- 26mm x 20.3mm

- 1.6mm thickness

- HASL lead free

- Red solder mask

- 50 pcs = $23

Shipping options were:

- DHL/FedEx-IP $22 (3-7 days)

- EMS $32 (22-27 days, more expensive and slower so pointless)

- China Post $7 (37-52 days)

Total cost for 50 boards was $23 + DHL shipping $22 = $45. My order was confirmed on 2020-05-20 at 10:23am. The boards arrived in Finland, delivered to my door by DHL, on 2020-05-26 at 7:36pm – 6 days later.

JLCPCB

For comparison purposes, I also had JLCPCB make me the same board. The order process is similar to PCBway, with some differences. There is an “Instant Quote” form on the front page, but it’s already filled with default values, and just clicking OK opens up a page with “Upload Gerber” on it. Handy – no need to remember or write down the PCB dimensions.

JLCPCB has fewer options for the board, but all the ones that matter for simple cases are there. There are 6 different PCB (really solder mask) colors (some cost extra, only white silkscreen), 3 different surface finished (leaded and lead-free HASL, and ENIG), 1oz or 2oz Cu, only one type of FR4 board, 0.4–2.0mm thickness, etc. Just like with PCBWay, it costs $3 to remove the order number, but there’s also a free option to add “JLCJLCJLCJLC” to the silkscreen in an inconspicuous place (under an IC for instance) that then gets replaced by the order number.

The pricing structure is a bit convoluted; as quantity goes up, an “engineering fee” of $4 or $8 gets added, but price per board may go down at the same time to cover the fee and then some, so it pays to fiddle with the quantity a bit. For instance, 75 pcs (of my board in lead-free HASL) would only cost $0.60 more than 50 pcs. If you choose 250 or more pcs, a notice pops up saying “We recommend you to prototype your PCBs before small batch PCB production” which of course makes a lot of sense.

The JLCPCB Gerber viewer lets you change PCB colour and surface finish (gold for ENIG, silver/gray for HASL), which is a nice touch.

I ordered 200 pcs of the board with HASL-RoHS (i.e. lead-free HASL) and black soldermask and was quoted $17.80 with a build time of 5–6 days. The shipping charge was $19.93 by “Europarcel”, including taxes if any. My order came to $39.73 (including $2 for 5 pcs of another PCB) and was submitted on 2020-05-20 at 10:28am. The Gerber review was promised to take “10–60 min during business hours” and was done in about 20 minutes by 10:50am. The package arrived on 2020-06-10 at 3:08pm at the local post office, just about 3 weeks later, where I picked it up the following day.

Oshpark

Oshpark is based in USA, somewhere in California I believe (so you can bet their environmental credentials are impeccable). Their website has a drag and drop target titled “Upload Gerber” on the front page – just as it should be, let’s get down to business and save the chitchat for later. You can even upload KiCad or Eagle files if you so choose.

Oshpark offers very few options. The board can be either 1.6mm and 1 oz Cu, or 0.8mm and 2 oz Cu, no mix and match here. There is a “Medium Run” option with larger (10+) quantities, but the board has to be larger than 100 square inches, so that wasn’t an option here. “Super Swift Service” lets you jump the queue a bit. “Flex” is “2 layer PCBs on a thin, flexible substrate,” whatever that means. “After Dark” is black PCB with a clear solder mask (default is purple solder mask). ENIG is the only surface option.

Unlike PCBWay or JLCPCB, where the price is the same for all boards up to 100 cm^2, Oshpark prices the boards strictly according to size. The smaller the board is, the cheaper it’ll be (I believe there’s a lower limit to how tiny boards they will make though).

I ordered 3 pcs with the After Dark option for a grand total of $4.10 including US Mail shipping with a quoted delivery time to Finland of 5–21 days. Even though the website says there is no tracking, the package can be tracked – up to the point where it is lost, as seems to have happened to another PCB I ordered earlier. The order was submitted on 2020-05-20 at 10:49am. It was shipped almost 2 weeks later on 2020-06-03 and was delivered on 2020-06-17, some 28 days after order submission.

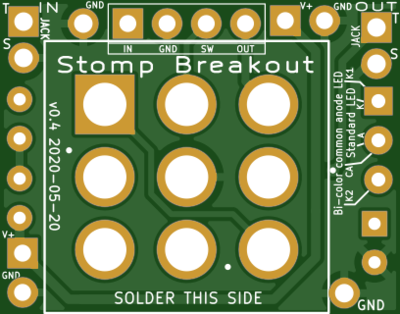

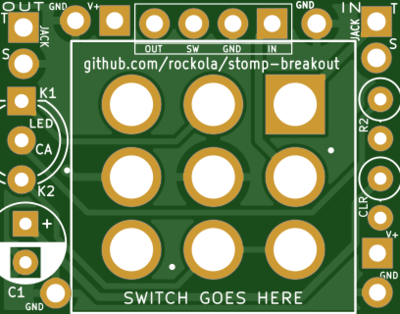

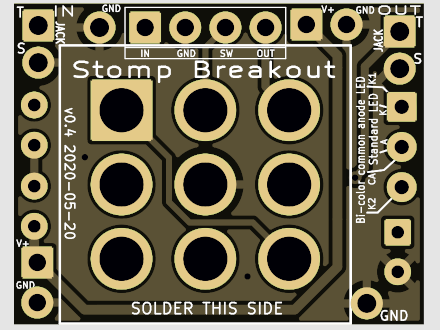

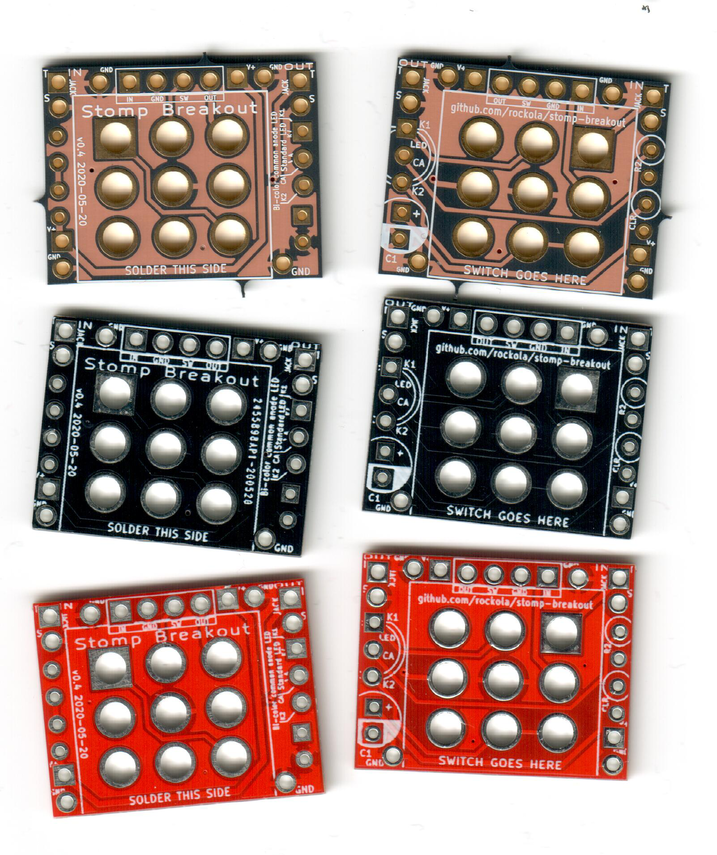

Board quality

Undoubtedly the best quality PCB was the one made by Oshpark. The comparison is a bit apples and oranges, as it’s also the only one with an ENIG surface. Still, the silkscreen leaves nothing to wish for, unlike the two Chinese boards – even the tiniest text (way smaller than what they guarantee to be able to render) is sharp and readable – and the After Dark board looks just great, with a truly black substrate instead of just coloured solder mask. From previous experience I know that their default purple boards also look just great. The manufacturing process does leave some nibs on the board edge where it was attached to other boards. It’s easy enough to file these away (and it’s just cosmetic anyway so no harm done if they’re left as is) but it’s something that doesn’t need to be done with the two other PCBs.

The PCBWay and JLCPCB boards are quite similar, but there are some differences, notably with the silkscreen. The small text isn’t particularly sharp on either, and there seems to be more of a tolerance with how the boards are cut. The PCBWay board seems to have a slightly larger margin around holes where the silkscreen text is removed. Some of the text on the JLCPCB board seems to have moved slightly; I don’t know whether this is because of their manufacturing process or a manual intervention by staff. Everything seems to be within spec though. Looks like the surface is flat on one side and a bit raised on the other side on both, but interestingly the flat side is front on the PCBWay board and back on the JLCPCB board.

Conclusions

All three manufacturers (Oshpark, JLCPCB, PCBWay) delivered what they promised, when they promised. All boards work just fine for their intended purpose. There are cosmetic differences, but nothing to be alarmed about. I would not hesitate to place an order with any of the three.

All three have Gerber viewers for checking the to-be-built board. It’s a matter of preference whether the Oshpark viewer, with its static renders of each layer and helpful text explaining what is going on, is better than the JLCPCB viewer with its colour options or the PCBWay viewer with its panning feature and SVG download.

PCBWay has the largest variety of board options, with Oshpark having next to no options. For a quick’n’dirty low-power prototype none of the cosmetic options will matter, but thick copper, another surface finish (for instance, only PCBWay offers immersion silver) or heat-resistant/heat-conductive board material may be vital for some applications. I am but a hobbyist (for now) who tinkers with guitar pedals, so my needs are quite modest.

The Oshpark board is the highest quality and also best looking, but already has the advantage with a better (and more expensive) surface finish. The JLCPCB and PCBWay boards are quite similar and might even be made in the same factory (Update: PCBWay assures me they are not), although there are enough differences in details so that there is definitely a different process involved in getting from Gerber to finished board.

Oshpark is the clear winner when it comes to shipping; JLCPCB or PCBWay could not come close to the total cost. $4.30 for 3 boards SHIPPED to Finland? Incredible. DHL (PCBWay) and Europarcel (JLCPCB) cost about the same but DHL was much quicker, so PCBWay definitely has the edge there.

Which PCB manufacturer will I choose in the future? If I just need a board or two, the board is small, and I’m not in a hurry, I’ll go with Oshpark. If I need a pile of identical boards, I’ll probably choose JLCPCB or PCBWay (or maybe another option, feel free to chime in in the comments), with the choice depending on quantity and options. If I need a board with more exotic options (that immersion silver again), it looks like PCBWay is better equipped to offer those than either of the other two. PCBWay also got the board done a bit quicker. On the other hand, JLCPCB seems to have slightly more competitive prices.

There are a few PCB prototype manufacturers within the EU, but judging by their pricing it seems they cater mainly to the professional market and not so much to hobbyists. For instance, Eurocircuits would charge about 42 EUR (+5e shipping) for 1–5 pcs of the review PCB. That could still be an OK deal if you’re in a hurry (though international shipping even within the EU is a mess right now) and just need the one prototype, and of course in a professional context that is not expensive at all.

I’ve only covered 3 out of a huge number of PCB manufacturers out there, so let me finish with this thought: even if germanium transistors have all but disappeared and through-hole is on its way out, it’s a pretty good time to be an electronics tinkerer right now.